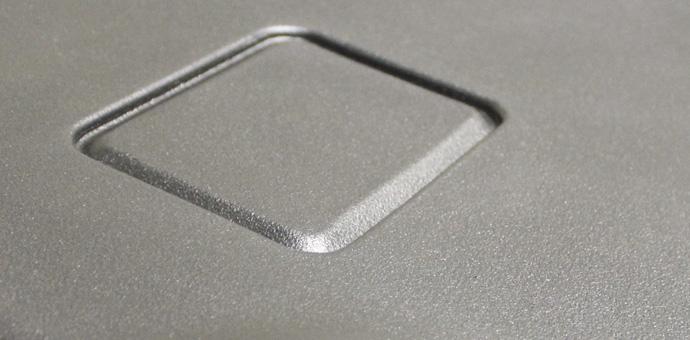

The Tecni-Form range of specialist finishing processes is unmatched, including numerous grains and textures, colours and metallic finishes

RM Plastics – Colours, Textures & Finishes

There are many areas in the home and garden where rotationally moulded plastic components are suitable. In the domestic environment, aesthetics are often especially important, and this is where Tecni-Form’s innovative approach can be particularly helpful to your concept. Their range of specialist finishing processes is unmatched, including numerous grains and textures, colours and metallic finishes.

Rotationally Moulded Hollow Containers

Simple mouldings such as baths, hot tubs, pond liners, coal bunkers, domestic tanks for oil and water, plastic pots and planters, washbasins and wheelbarrows can all be made to look good with colours, speckles and textures.

RM Plastics for More Sophisticated Mouldings

More complex products can be achieved with assembly and finishing techniques, and colours and textures can be applied just as in simpler plastic parts. Garden furniture and figures, components for lawnmowers, water softening equipment, wet & dry vacuum cleaners, carpet and floor cleaning machines, and heavy duty jet washers are just some of the plastic components that benefit from the rotomoulding technique.

Rotomoulding is often used to produce sanitary items for the home – from raised toilet seats for the disabled to hot and cold water storage cisterns, septic tanks and sewage pipe fittings.

Example of our Work

Tecni-Form can even rotationally mould housing for hi-fi speakers with a modern sleek design. Manufactured in high-impact polypropylene and painted in soft-touch paint.

Have a look at the section describing the full rotational moulding process: it may inspire some ideas for your area of interest.