How Rotational Moulding Can Deliver Strength for Wall- Mounted Products

Tecni-Form provided constant support whatever the subject was: manufacturing, design or prototyping – Mr Hesnard, Director of Baby Point

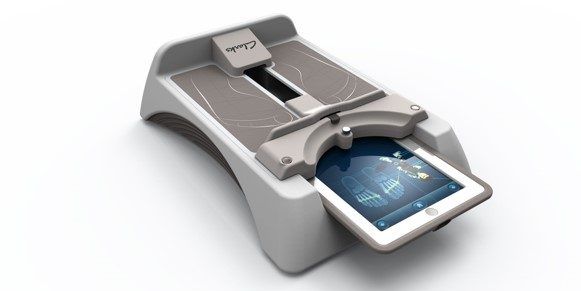

Baby Point Ltd is the main provider of baby changing facilities for mainstream retailers, shopping centres, airports and leading attractions in the UK. Baby Point Ltd has tasked Tecni-Form with the design and manufacture of a wall mounted baby changing table with a high load-bearing capabilities (upto 125kgs) and an antibacterial surface to meet health and safety regulations.

The first wall mounted baby changing tables developed by Baby Point and Tecni-Form, optimised the available space even in small washrooms and are an extremely well engineered products complying with both safety and hygiene regulations

Outstanding Strength and Hygiene by Design – The Solution

To achieve sufficient strength it is essential that the right resin was selected. The Tecni-Form team suggested a high rigidity polypropylene for the rotational moulding process, the first time this polymer has been used for this application.

Furthermore, to both guarantee strength under load and provide a hinge system for wall mounting, an assembly of reinforcing steel is moulded into the cantilever style structure with the durable rotomoulded hollow moulding filled with a rigid PU foam.

The new wall mounted baby changing station demonstrates how Tecni-Form’s versatile engineering capabilities can add value to a product where safety and rugged construction are an absolute must.

In fact they achieved double the weight bearing requirements for baby changing tables, because being capable of taking loads up to 120kgs takes into consideration that parents may lean on the station.

Hygiene is another important factor that needs to be taken into account at the design stage. Polypropylene offers higher hygiene standards than the medium or high density polyethylene used for other makes of baby changing tables. With its polished surface it is easy to maintain and by adding anti-microbial additive to the polypropylene compound it provides outstanding hygiene and guards against bacterial spread.